When I first introduced Lean to the Benchmark team I was a little uncomfortable with a comment from Paul Akers, author of 2 Second Lean, stating that “it all starts in the bathroom.” He maintains that there is no better place to start to build and maintain a culture of continuous improvement than in the bathroom. Everyone uses it, so it’s a perfect place to apply the 3 S’s: sweep, sort and standardize.

- Sweep – a clean environment improves morale and actually makes it easier to identify equipment deterioration and/or malfunction

- Sort – sort everything and remove what is not necessary to the job at hand and get rid of all the clutter and junk

- Standardize – this involves building consensus in the workplace for best practices so that everybody understands what to expect and what is expected of them

I wasn’t sure how the team would react to being asked to clean the bathroom. We have a fabulous cleaning service and I certainly wasn’t trying to put them out of business. The real goal was to get everyone to start thinking LEAN. So I apprehensively shared this 3 S-ing idea with the team in our Daily Lean 19 meeting and was surprised by the positive reception. Everyone was on board!

My advice for people wanting to create a Lean culture is to start in the bathroom and roll it out slowly from there. Go ahead, do it in the bathroom! – Paul Akers

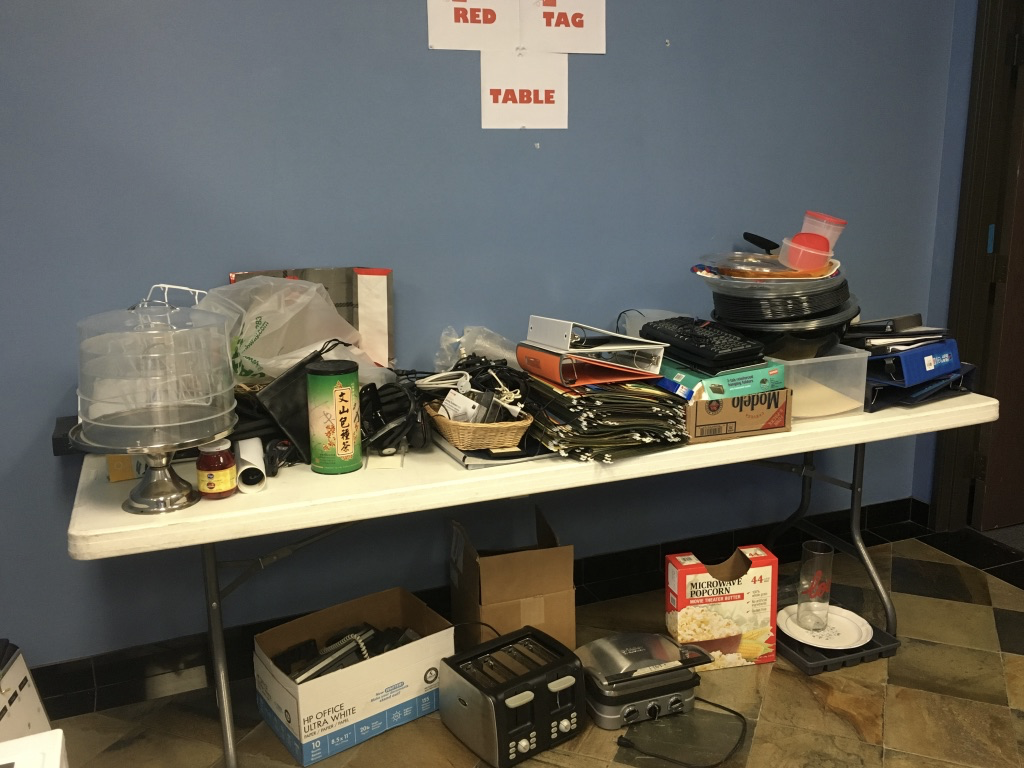

We decided to divide our worldwide headquarters into seven main regions: men and women’s bathroom, kitchen, lobby, main conference room and supply room. We did an enormous 3 S-ing day where everyone was assigned to one of the areas and we went to town getting everything spic n’ span. It was actually fun. We made a Red Tag table for stuff that had been laying around for ages. We invited people to take anything on the table. Whatever was left over would be donated, recycled or trashed. We got rid of loads of junk that was lowering our productivity.

Just like Paul recommended, we went through each area- including the bathrooms- and 3S-ed.

Everyone- including our CEO, Curt Keller, takes a turn maintaining a different area for the week. We announce the weekly 3S-ing assignments in our Daily Lean 19 meeting and in Slack. It rotates around and thanks to our standardized visual procedures, they know exactly what needs to be done.

Now our bathrooms are spotless all the time … and our cleaning service loves us as we’ve made their job easier!

Building a Lean culture requires standardizing and simplifying everything. By starting with the bathroom, you embrace one of the main tenets of Lean which is respect for people. Leaving the bathroom cleaner than you found it is a very basic sign of respect and courtesy for others. The toilet seat is down and there is no icky stuff to navigate.

I’d love to hear what you have done in your office to help build a Lean culture. Please share in the comments!